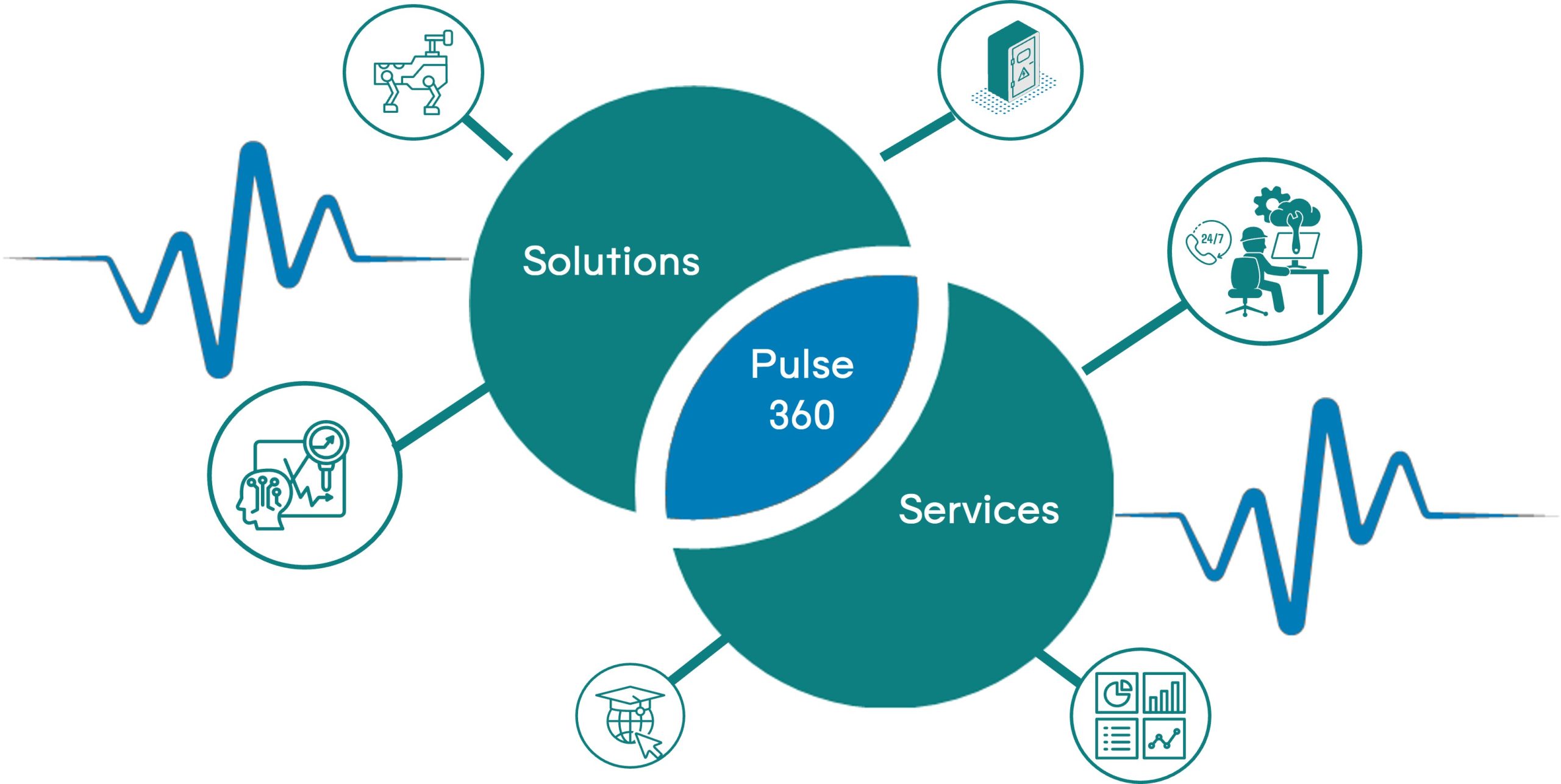

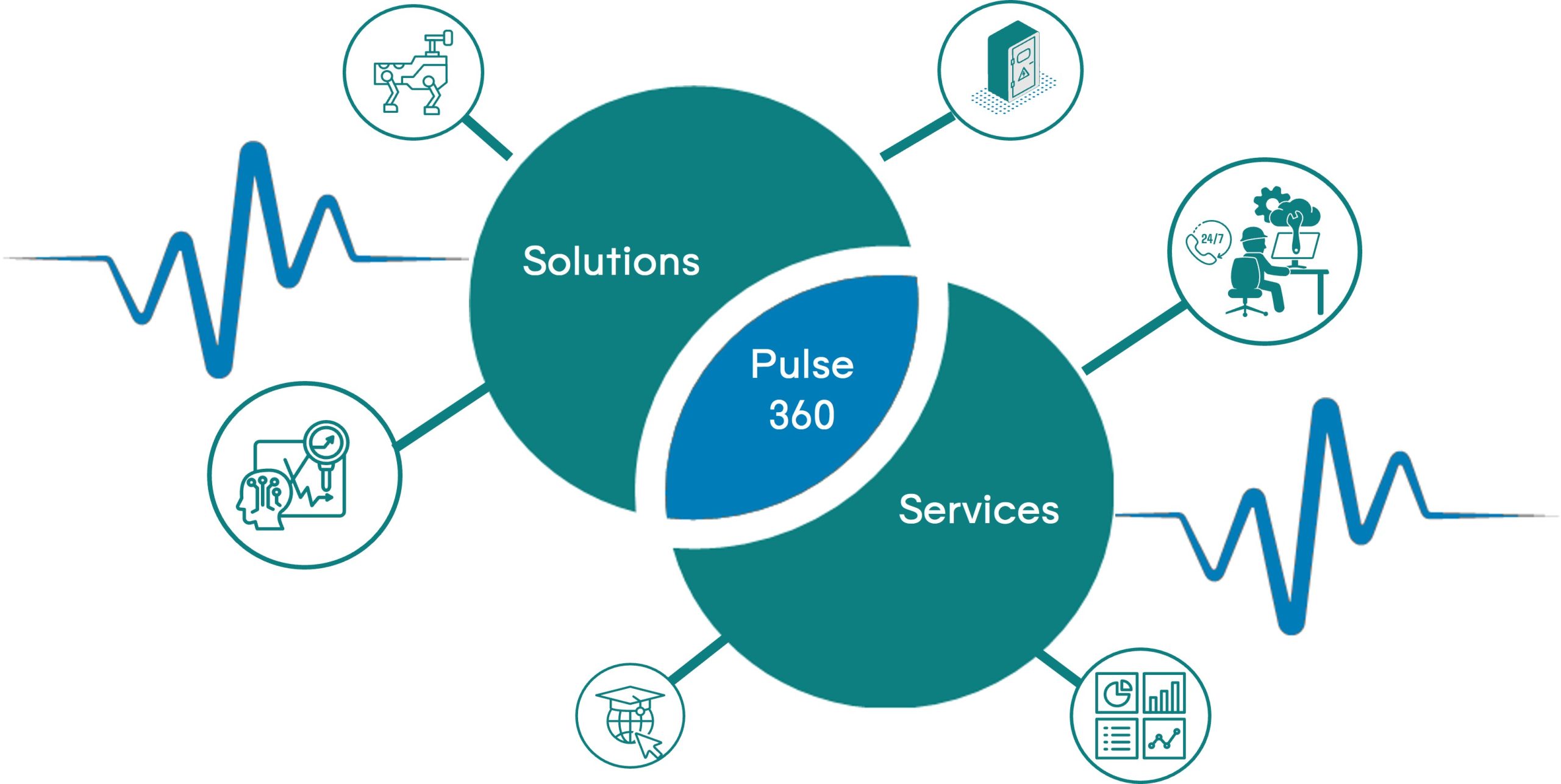

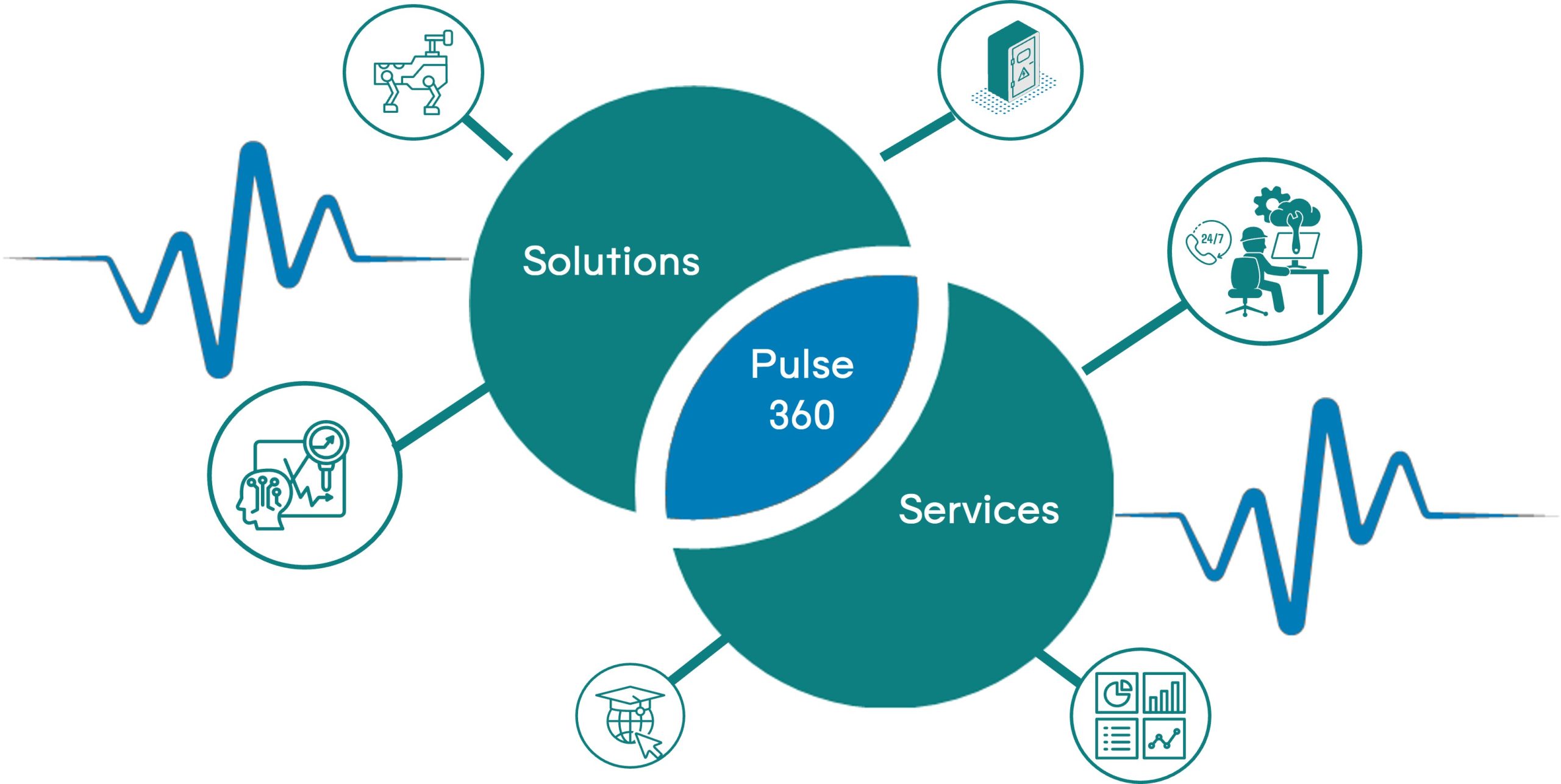

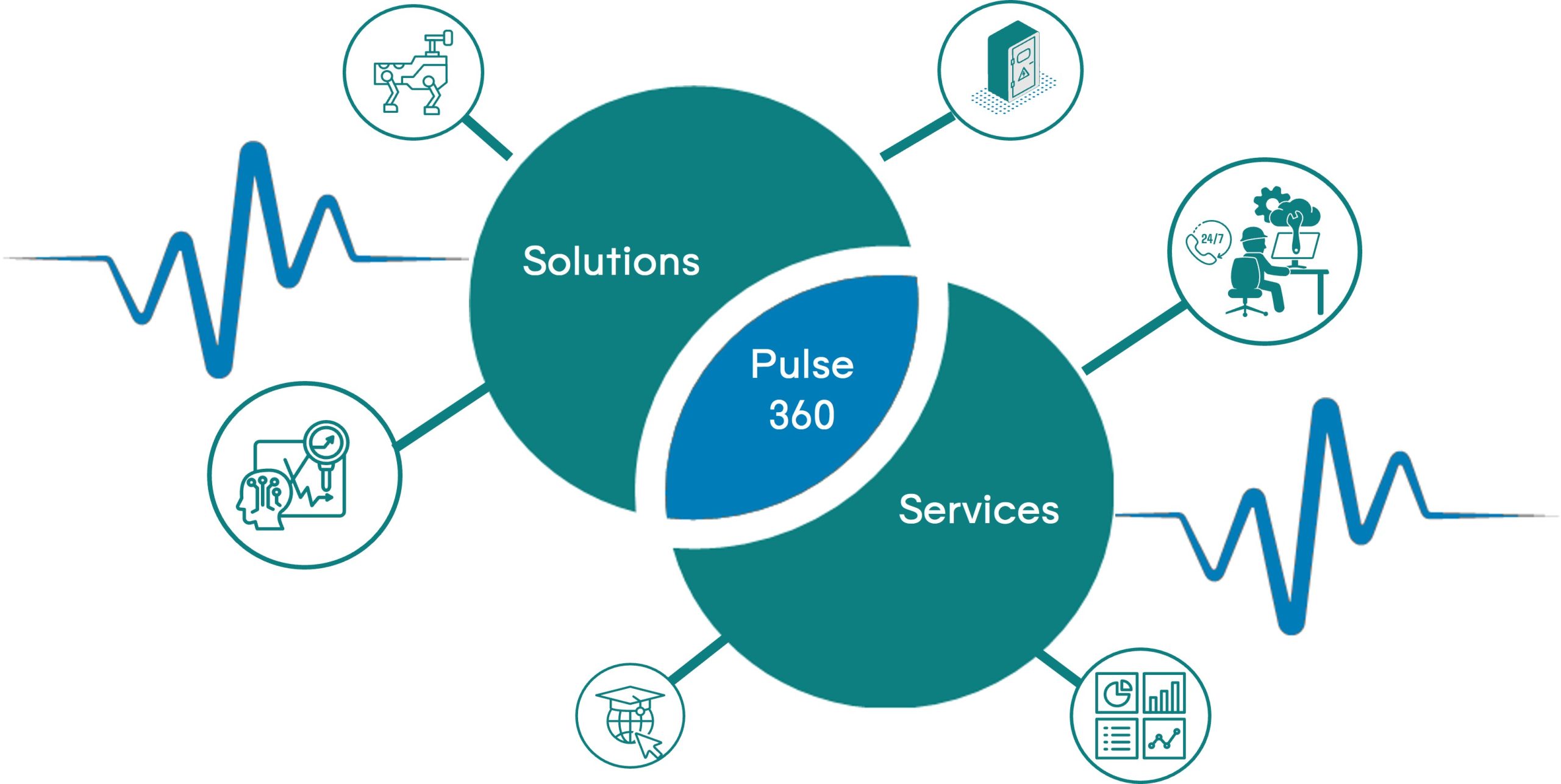

Digital services around your waste-to-energy plant.

High availability is crucial to the successful operation of any plant. Kanadevia Inova Pulse is a digital ecosystem that combines digital standards to create a service solution tailored precisely to your needs.

The right service at every phase of the plant life cycle

We provide effective, expert advice and support throughout the life cycle of your plant. We draw on many years of experience and in-depth know-how gathered in the course of our R&D to keep your plant in line with the specific local and operational requirements and regulations. Our Kanadevia Inova Pulse digital ecosystem guides and supports you through the whole life cycle of a single piece of equipment and the entire plant.

Kanadevia Inova Pulse: future-ready with our digital solutions

Kanadevia Inova Pulse is a portfolio of innovative digital solutions that will enhance the performance and maintenance of waste-to-energy (WtE) plants. Whether you’re embarking on a new construction, a renovation or an upgrade of a renewable gas facility, there’s a solution tailored to every phase of your facility’s life cycle.

Stay tuned, we will update this area with new digital solutions continuously.

Bulky Waste detection

Detect bulky waste with the help of AI

Bulky waste detection powered by AI will

- help your crane operators recognise bulky waste items

- reduce unplanned shutdowns

- increase the availability and efficiency of your plant

A bulky waste item stuck in the feed hopper or downstream sections of the combustion system can reduce plant availability and plant efficiency. To avoid this risk, Kanadevia Inova has developed a new AI-driven solution for detecting bulky waste. The waste dumping gates are continuously monitored by a set of cameras and the recorded video stream is analysed in the detection software. Newly arriving objects are visually checked and potential bulky waste items are identified. The provided web application alerts plant operators to bulky waste items. A customised add-on is also available to detect specific types of problematic items.

Contact for more information: dss.sales@kanadevia-inova.com

Web application example

Matress detection

Ram feeder and grate control

Ram feeder and grate control

Stay at the leading edge of WtE technology for

- greater convenience and cybersecurity

- lower operational costs

- increased plant availability and performance.

Our ram feeder and grate control solution uses proportional valves and continuous position sensors ensuring that ram feeders and grate elements move smoothly and in sync. It supports four selectable grate movement patterns to match varying combustion needs and enables automatic stroke reduction in case of blockages.

Our system remains operational even during sensor faults and allows for guided troubleshooting directly via a touch panel. With maintenance-free sensors, automatic valve curve recording and remote access, it simplifies maintenance and improves reliability. Designed for seamless integration, it enhances combustion symmetry, reduces wear and supports efficient, stable plant operation.

Contact for more information dss.sales@kanadevia-inova.com

Autaro combustion control

Combustion control system

Kanadevia Inova’s AutaroTM combustion control system does more than just produce steam on a stable basis.

The main job of a combustion control system is to ensure smooth plant operation and the constant production of steam. But another key factor is flexibility. Fluctuations in waste compositions and calorific values at different plants require correspondingly flexible processes – and thus the right control system. This is also important if the waste fails to burn as desired. In such cases it must be dried and moved, and oxygen fed in additionally.

The AutaroTM combustion control system allows a plant to operate at significantly lower oxygen levels, keeping the oxygen content downstream of the boiler below 4% – an impressively low value. With combustion optimised by the adaptive reduction of oxygen, lower NOx is achieved without exceeding CO limits. This in turn leads to a reduction in the use of DeNOx additives. Using less air also produces less fly ash and flue gas. The end result is that new plants can be designed with smaller flue gas systems.

AutaroTM makes a plant sustainable by considerably reducing energy consumption and the overall environmental impact. In retrofits, new reserves can be created by operating at lower oxygen levels, meaning that higher loads can also be achieved.

Contact for more information: dss.sales@kanadevia-inova.com

More information:

Grate & Autaro combustion management

Fact Shet Autaro Lausanne

Project Lausanne

Fabric filter control & optimisation

Fabric filter cleaning system

A simple and independent system for intelligent monitoring, control and optimisation

enabling highly convenient and effective maintenance

lowering operational costs

increasing plant availability and performance

The fabric filter control and optimisation solution monitors, controls and manages the cleaning of filter bags. Filter malfunctions are reported instantly to the operator. The system optimises the service life of filter bags, minimises cleaning air consumption and simplifies maintenance. It’s easy to use and highly flexible.

Cleaning pressure adjustment (patented)

The filter cleaning system uses an electro-pneumatic air pressure regulator to lower the cleaning pressure whenever possible and increase the cleaning pressure during high-demand peaks. This saves electricity and helps extend the lifetime of the filter bags.

Filter bag monitoring

The filter cleaning system uses the volumetric flow to calculate the current gas flow speed and work out the time required for a cloud of particulate emissions from chamber X to reach the sensor. If a bag is damaged, the particulate signal exceeds the monitoring threshold set in the system. In this case, a malfunction message is generated, precisely localising the filter bag line in question. Changes in the particulate signal over longer observation periods also enable the lifetime of filter bags to be predicted.

Valve function monitoring

The system allows early detection of a valve failure (not opening, not closing or no power) and differentiates between mechanical and electrical failure. The damaged valve can be precisely localised for quick and efficient maintenance.

Contact for more information: dss.sales@kanadevia-inova.com

Rapping control & optimisation

We keep your boiler clean

Stay at the leading edge of WtE technology to

- prevent premature and excessive boiler fouling

- achieve longer and more stable operating times

- create precise overhaul schedules

Systematic monitoring is the only way to determine for sure if a boiler rapper is working properly. Our one-of-a-kind rapping control and optimisation solution is very helpful. It checks the exact level and location of fouling in the boiler by listening to harp harmonics and then uses laser positioning sensors to move the rapping carriage straight to the problem area. The online solution helps you safeguard or improve the profitability of your plant by continuously and automatically checking the functional integrity of the rapper during operation – letting you know for sure whether it’s doing what it should be. It’s available for carriage rapping systems.

Contact for more information: dss.sales@kanadevia-inova.com

Stay tuned, we will update this area with new digital solutions continuously.

Stay tuned, we will update this area with new digital solutions continuously.

Stay tuned, we will update this area with new digital solutions continuously.