KOM+PRESS - Dewatering Press

KOM+PRESS

Dewatering Press for the Separation of Fermentation Residues

KOM+PRESS open at the side

KOM+PRESS offers impressive service-friendliness. Low wear and tear reduces operating costs. In addition to its use in Kanadevia Inova AD plants, it is suitable for retrofitting existing biogas installations.

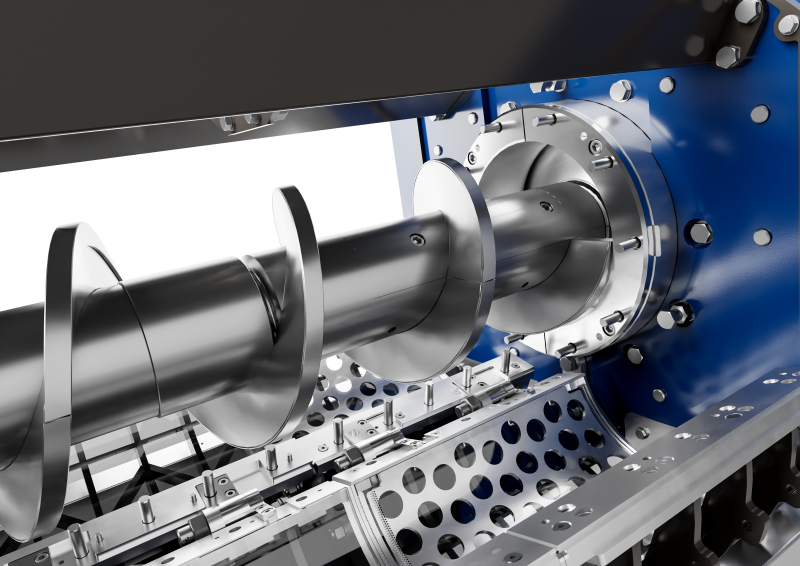

Extended Operating Time Thanks to Precise Technology

Equipped with a double-bearing worm shaft and armoured spirals, the KOM+PRESS ensures precise dewatering. The pre-mounted bearing relieves the gearbox of radial and axial forces, which has a positive effect on the operating time of the press. At the same time, the optimized design of the press head reduces both the force required by the machine and the material abrasion. In combination with the wear protection fitted at relevant points and the adapted wear inserts in the inlet hopper, these technical advancements guarantee a long service life for the entire system.

High Serviceability

Thanks to swivelling sieve baskets, the heavily used sieves and wear parts of the press screw can be replaced by a single person in a few simple steps. This avoids time-consuming and cost-intensive maintenance. The graduation of the wear rings from the jam cone allows them to be changed quickly and efficiently without dismantling the worm shaft. By using replaceable spirals, the most intensively stressed parts of the screw can be exchanged quickly and by one person. Last but not least, the function-oriented design allows easy accessibility and facilitates cleaning.

The sieve baskets can be replaced by a single person in a few easy steps.

Replaceable spirals allow the most stressed part of the screw to be exchanged.